More space for XXL X-ray technology: ground-breaking ceremony for new laboratory hall in Fürth

The X-ray Technology Development Center at Fraunhofer IIS creates space for new ideas: With the construction of a laboratory hall for another high-energy X-ray system, Fraunhofer IIS is decisively expanding the field of application of XXL computed tomography (XXL-CT), which is in high demand, and creating ideal conditions for a globally unique range of X-ray systems. The new high-tech system is scheduled to go into operation as early as 2026.

The start of the construction work at the Fürth site of the Fraunhofer Institute for Integrated Circuits IIS was celebrated with partners from state and local politics. Dr. Markus Wittmann, Ministerial Director of the Bavarian Ministry of Economic Affairs, Petra Guttenberger, Member of the State Parliament, Dr. Thomas Jung, Mayor of the City of Fürth, and Horst Müller, Economic Affairs Officer of the City of Fürth, visited the site and learned about the plans of the Fraunhofer researchers.

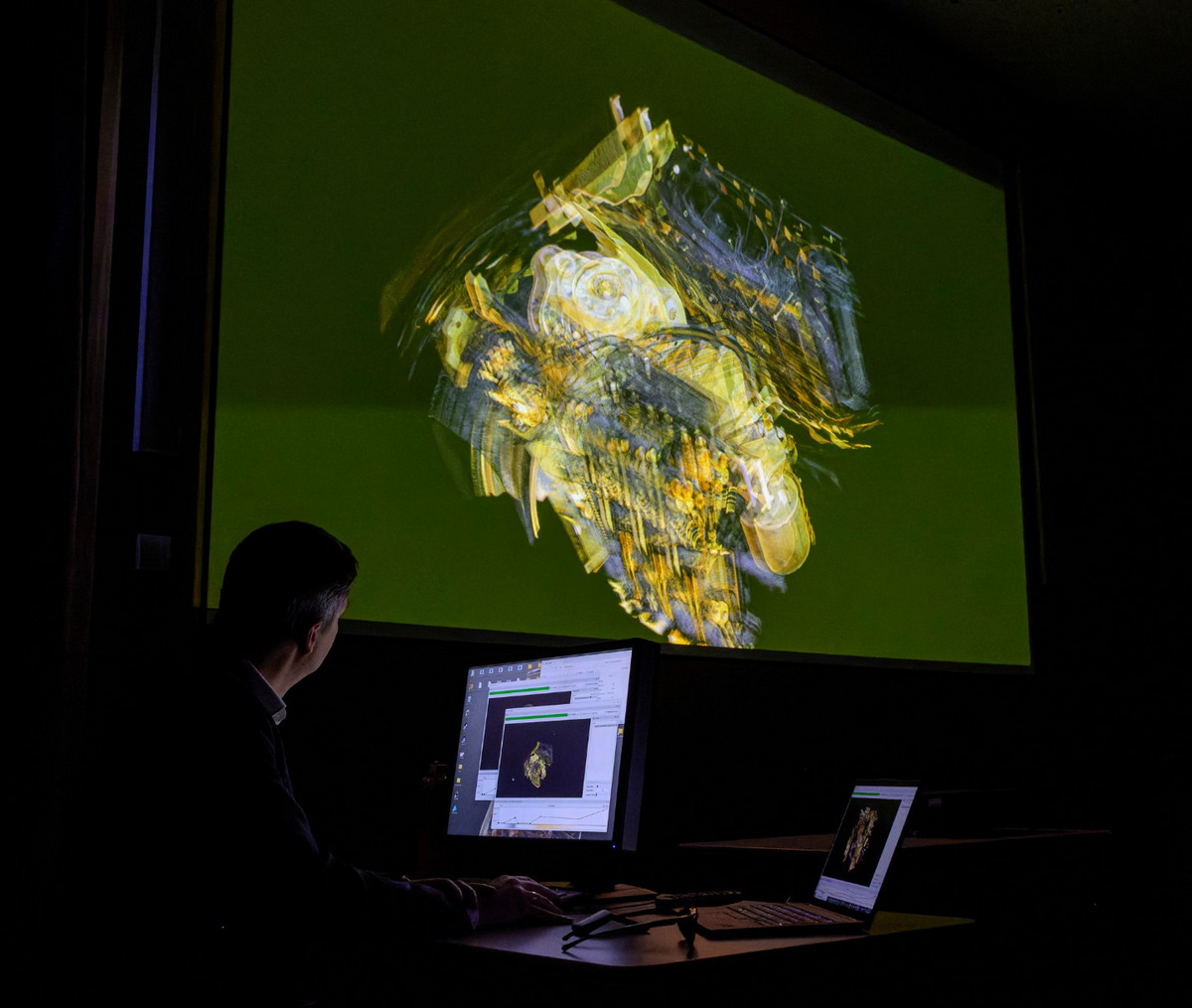

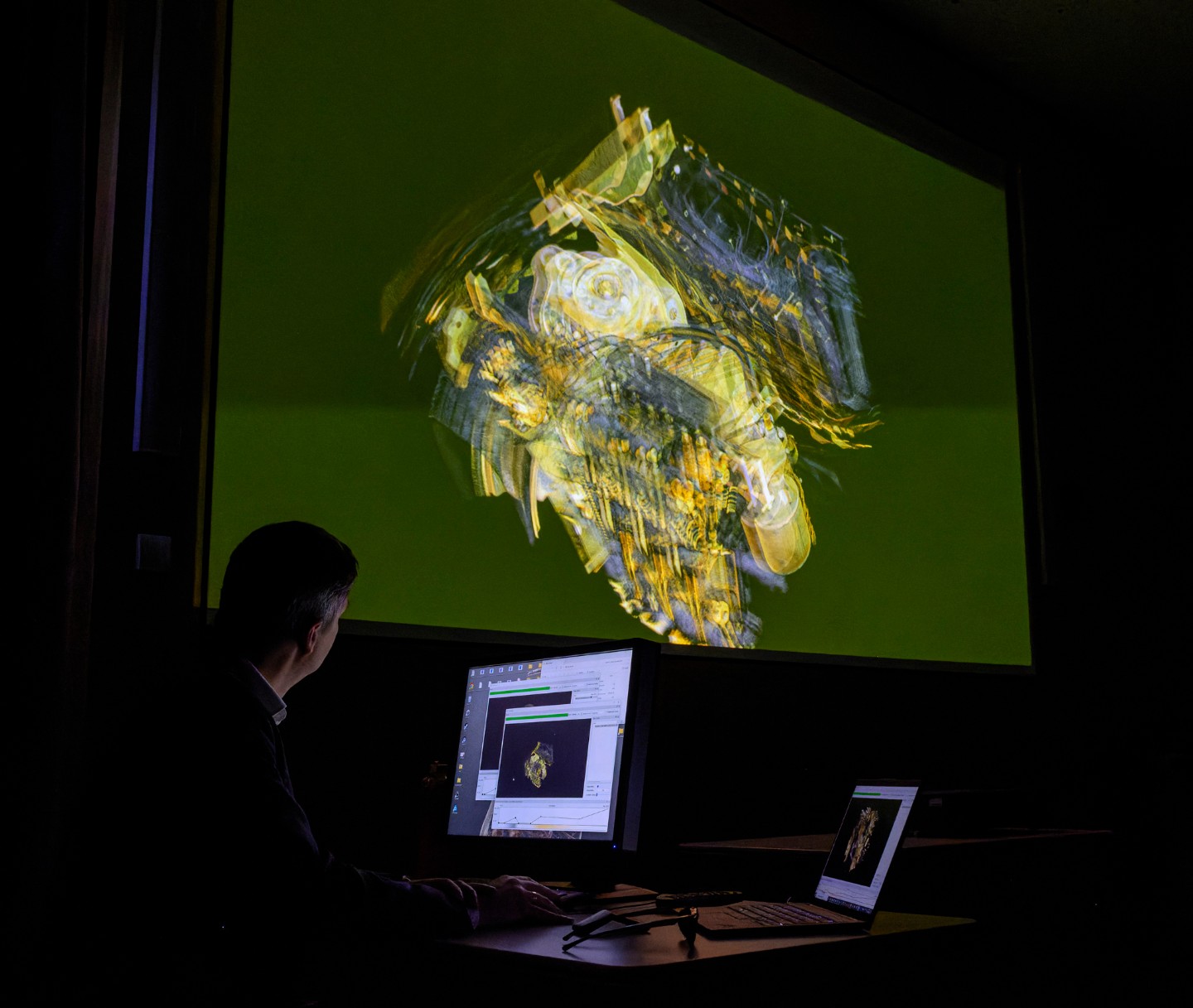

With the XXL CT system, which went into operation in 2013, the Fraunhofer IIS Development Center for X-ray Technology has set the global standard for three-dimensional imaging of internal and external structures of large objects such as entire vehicles and sea freight containers. In addition to the sheer penetration capability of the system, which makes it possible, among other things, to visualize the finest details in fully assembled battery storage units, the measurement results are characterized by a particularly high image quality. Until now, however, the imaging geometry of the XXL CT system has limited its application, as massive, elongated objects such as the battery storage unit of a modern electric vehicle had to be positioned on edge in order to achieve high image quality.

Oversized “tube” for industrial applications

The new building will now provide the necessary space for the next development stage of XXL CT: the new system in so-called gantry design is reminiscent of the “tube” known from medicine, in which the radiation source and X-ray detector rotate around the person lying down.

The design of the system has numerous advantages: the test objects remain in their “natural position”, which considerably simplifies handling and increases the safety of the usually very valuable test objects. Sensitive cultural assets, for example, can be digitized without exposing them to avoidable risks from uprighting.

In the field of electromobility in particular, the construction method opens up a wide range of interesting application possibilities: battery storage systems can be examined in various service life simulation or load phases in a fire-retardant containment in order to better understand the internal processes in the event of damage.

Data processing

The data volumes generated by the system of around 10,000 x 10,000 x 10,000 voxels represent a particular challenge for the researchers. Image processing and evaluation are carried out with data sets that can comprise several hundred gigabytes. Here, the Fraunhofer researchers benefit from the results of the “Big Picture” project, which was funded by the Bavarian Ministry of Economic Affairs at the Fürth, Deggendorf and Passau sites. As part of the project, new methods for handling very large amounts of data were researched, such as those generated in particular by high-energy computed tomography. The project results were consistently developed further and now represent an essential building block for data handling in high-energy X-ray systems.

Comments on the event:

Prof. Albert Heuberger, Managing Director of Fraunhofer IIS:

“X-ray energies of several megaelectronvolts are required for the radiography of very large objects. However, high-resolution imaging with these high energies as a computer tomogram was not technically feasible until now. We took up the challenge and broke new ground with our XXL computed tomography system, which was time-consuming and demanding. Nevertheless, we believed in our idea and created a ground-breaking, unique system that redefines the limits of what is possible in industrial X-ray technology. With the next generation of our XXL-CT high-energy X-ray system, we are continuing on this path. It will open up numerous completely new areas of application for our customers.”

Dr. Norman Uhlmann, Head of the X-ray Technology Development Center at Fraunhofer IIS:

“We are very pleased to be able to expand our equipment pool once again with a high-energy X-ray system! The special system geometry of the planned XXL system in gantry design enables us to examine test objects such as vehicles or freight containers in their natural position. This brings significant advantages for us and therefore also for our customers. It allows us to eliminate unexpected force effects on the test object, which were previously caused by the need to erect the objects. In combination with our expertise in the field of X-ray image generation and data processing, we are excellently positioned for future challenges and offer our customers a unique range of services - from data acquisition and data processing to evaluation and decision-making.”

Dr. Markus Wittmann, Ministerial Director at the Bavarian State Ministry of Economic Affairs, Regional Development and Energy:

“The Fraunhofer IIS Development Center for X-ray Technology in Fürth has outstanding expertise in the field of non-destructive testing of a wide range of materials and products. The construction of a new laboratory hall, which is being funded by the Free State of Bavaria with 3.4 million euros, will make it possible to efficiently examine even very large workpieces, which is of particular importance for the needs of science and industry.”

Petra Guttenberger, MdL:

“The Fürth site of Fraunhofer IIS is a success story. The extension building will now open up further application possibilities that are of crucial importance for Bavaria and Germany as a business location and will once again achieve a successful link between research and industry. This is the nucleus for further jobs and thus for the prosperity of the people in our country.”

Dr. Thomas Jung, Mayor of the City of Fürth and Horst Müller, Economic Affairs Officer of the City of Fürth:

“The construction of the Fraunhofer Institute's new laboratory hall gives scientists the space they need for further important research. We are delighted that the work on the globally unique range of X-ray systems in the cloverleaf city will continue to manifest itself thanks to the Fraunhofer IIS and sustainably strengthen the science city of Fürth.”

© Fraunhofer IIS / Paul Pulkert | 3D scan, created with the existing XXL CT system in Fürth

© Fraunhofer IIS / Paul Pulkert | Groundbreaking ceremony for the construction of the new laboratory hall with (from left to right) Dr. Norman Uhlmann, Head of the X-ray Technology Development Center at Fraunhofer IIS, Dr. Thomas Jung, Mayor of the City of Fürth, Horst Müller, Economic Affairs Officer of the City of Fürth, Prof. Albert Heuberger, Managing Director of Fraunhofer IIS, Petra Guttenberger, Member of the State Parliament, Dr. Markus Wittmann, Ministerial Director at the Bavarian State Ministry of Economic Affairs, Regional Development and Energy

© Fraunhofer IIS / Udo Rink | Visualization of the XXL CT in gantry design scanning a car