The digital lighthouse in Forchheim: the High-Energy Photonics (HEP) Center

The HEP Center Forchheim from Siemens Healthineers is a showcase factory for the production of high-performance X-ray tubes, creating a “transparent factory” through comprehensive digitalization and automation. With technologies such as robotics, digital twins and dynamic capacity planning, it optimizes efficiency and flexibility and promotes collaboration between man and machine in a future-oriented working environment.

The HEP Center Forchheim is at the forefront of technological innovation in the field of medical imaging. As a state-of-the-art production facility of Siemens Healthineers, it is the birthplace of high-performance X-ray tubes and generators for imaging procedures. It features a complete end-to-end digitalization and automation approach and combines production, development and office areas. The HEP Center, which brings together two existing factories in Erlangen, was initiated in 2019.

With the integration of advanced technologies such as flexible cobot systems, robotics and sensors, the center transitions from traditional manufacturing to automation and digitalization. The HEP Center Forchheim is an example of Siemens Healthineers' commitment to transforming healthcare through cutting-edge technology and a skilled, lifelong learning workforce.

Creation of a “transparent factory”

The introduction of digital tools and automation is creating a “transparent factory” where everything is digitally connected - from the shop floor to equipment to logistical processes, including the building's digital twin. The digital transformation at the HEP Center aims to increase work performance, minimize risks and ensure knowledge transparency. Here are some examples of how this is being achieved:

- Digitalization of data: The HEP Center focuses on the transformation, generation, processing and networking of digital data in order to increase the added value of production and business processes. This approach aims to improve the input-output behavior of these processes.

- Automation: By using new hardware, at least one manual step in each process is automated, which is a crucial part of the digital transformation strategy.

- Digital shopfloor and visualization: Digital tools such as Digital Shopfloor Applications (DSA) and Manufacturing Execution Systems (MES) are used to visualize Key Performance Indicators (KPIs) and improve decision-making processes. Advanced planning and scheduling tools (APS) support detailed planning.

- Dynamic capacity planning: By optimizing shift balancing, the center has achieved a 15% space saving in the area of high-voltage conditioning, which contributes to efficiency and flexibility.

- Smart Factory Integration: The HEP Center is being developed as a fully integrated solution for a Smart Factory, which will be part of the Siemens Healthineers Campus Forchheim. This integration will bring together all the necessary disciplines - production, research and development and business management - to manufacture components for X-ray devices in a unique technological environment.

Digital twins optimize products and processes

The HEP Center uses data science and simulation functions to create digital twins of products, production and performance. Digital twins serve as a cornerstone for the optimization of products and processes. This model creates a virtual image of reality into which complex information from various sources can be integrated. This makes it possible to detect errors before they occur, prevent downtime, visualized collaboration, real-time insights, a fully digital development process and predictive intelligence, i.e. the ability to recognize patterns and forecast events based on statistical analysis.

Promoting human-machine collaboration

This environment fosters a culture of continuous learning and collaboration between humans and machines, each contributing their strengths to increase productivity and innovation. A dedicated program for employees supports cultural change and skills development. It ensures that the workforce is prepared to succeed in an increasingly digital and automated environment.

Background, sustainability and regional significance

At 350 million euros, the construction of the HEP Center is the company's largest single investment worldwide and underlines the importance of the Forchheim site. In the long term, around 700 employees will work at the new High-Energy Photonics Center.

The HEP Center will be built on an area of 69,000 square meters, which is roughly the size of nine soccer pitches. It will be operated almost CO2-neutrally. Siemens Healthineers has developed an energy concept that utilizes waste heat from the production processes and recovers heat through recoolers. Photovoltaic systems on the roof surfaces, highly efficient heat pumps and the use of green energy are intended to reduce CO2 emissions to almost zero. In addition, regional and recyclable building materials are used to minimize pollutant emissions.

The HEP Center plays a critical role within Siemens Healthineers by providing the “smart engine” for the company's most successful imaging devices, including CT, X-ray, angiography and mammography systems. These advances contribute to significant improvements in medical diagnostics and treatment, such as faster and more accurate breast cancer screening and minimally invasive cancer treatments.

Siemens Healthineers employs approximately 11,000 people in the Erlangen/Forchheim area. Forchheim serves as the global headquarters for the Diagnostic Imaging and Advanced Therapies business units as well as the main development and manufacturing site for computed tomography, X-ray and angiography systems. The expansion of the Forchheim site will make it possible to expand and optimize manufacturing capacities in the region in order to maintain and expand the global leadership position in the field of diagnostic imaging. is to be successful in an increasingly digital and automated environment.

© Siemens Healthineers

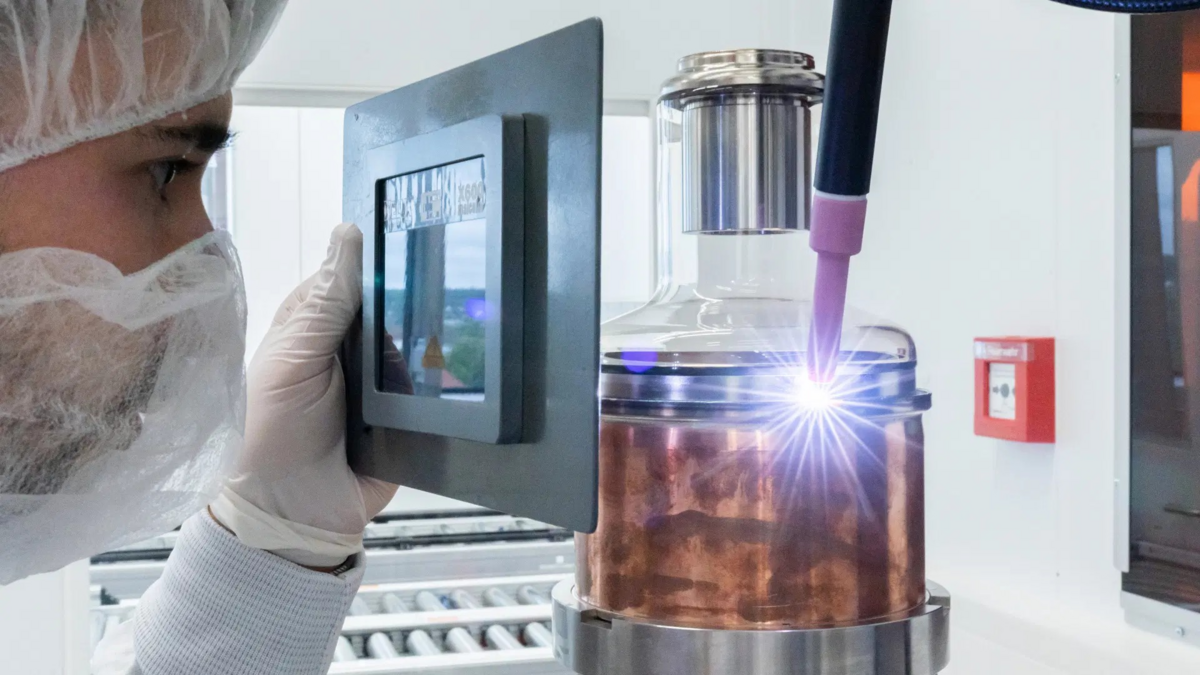

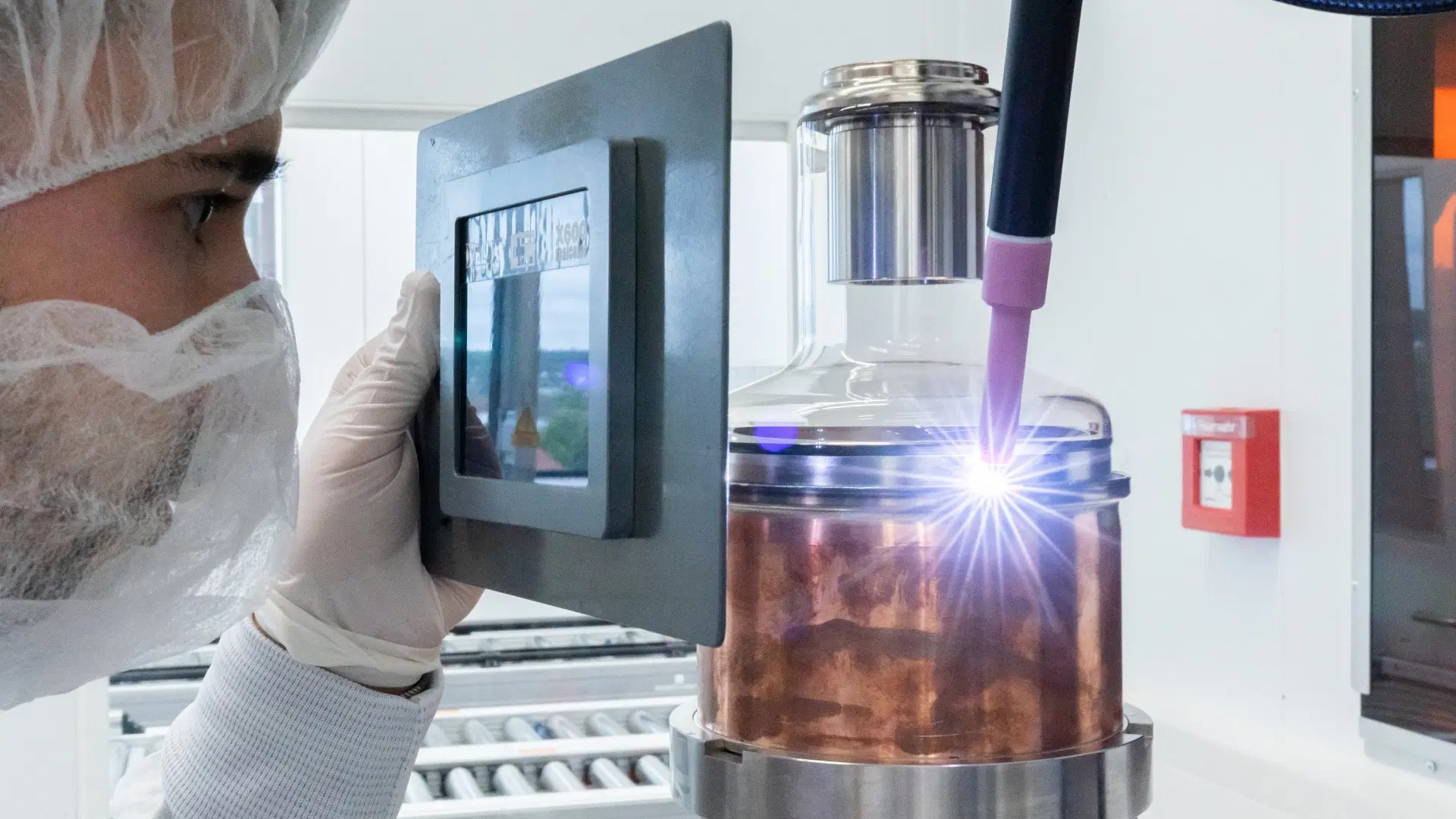

Welding of metal-glass X-ray tubes under clean room conditions. © Siemens Healthineers

Assembly of housing parts for the high-voltage supply of X-ray sources. © Siemens Healthineers

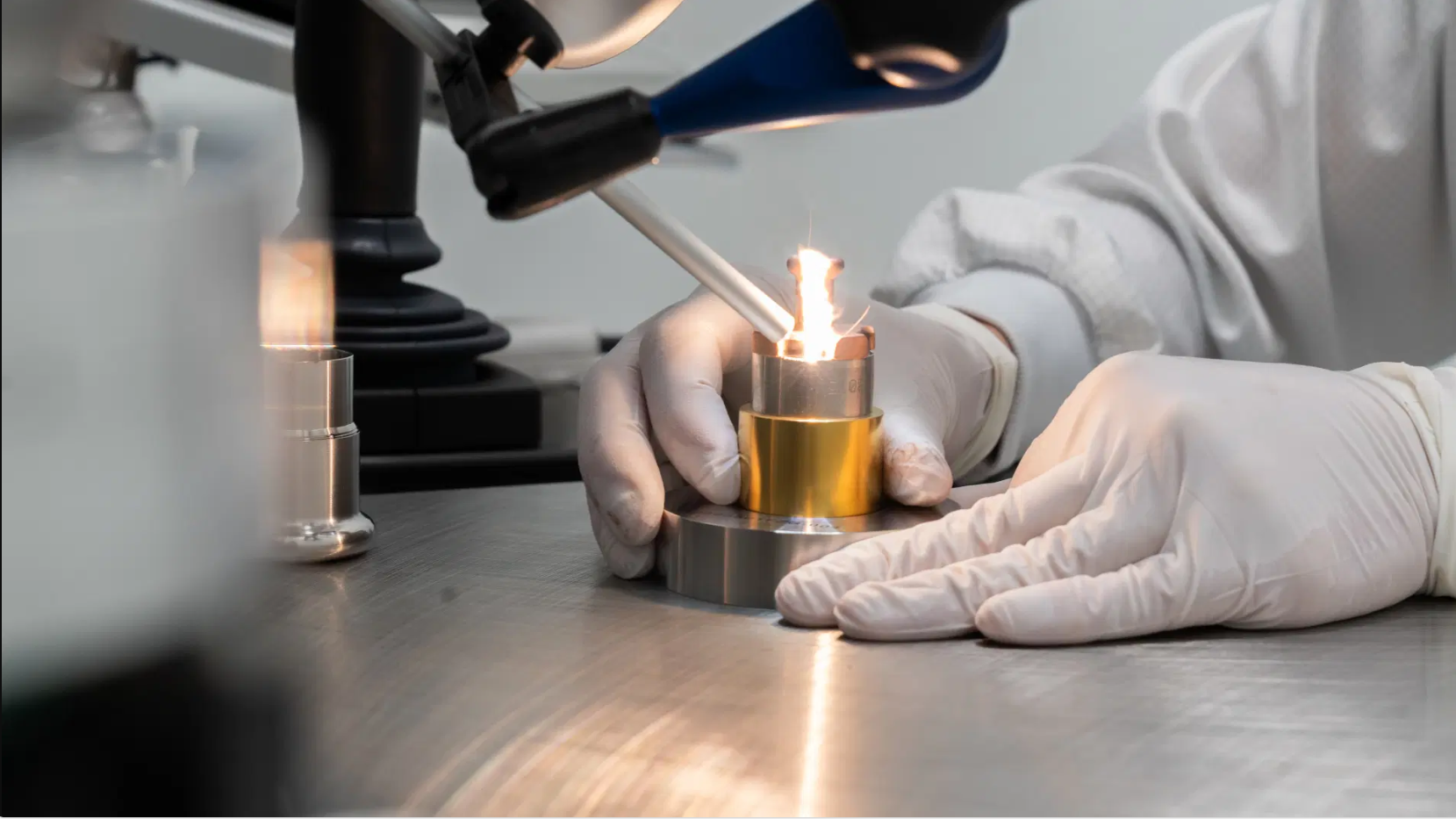

Laser welding of tubular components under the microscope in the clean room. © Siemens Healthineers